Save material, time and costs with deep-drawn parts

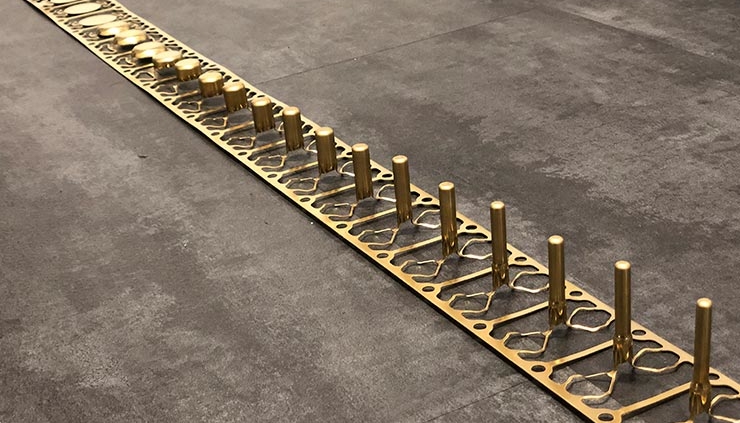

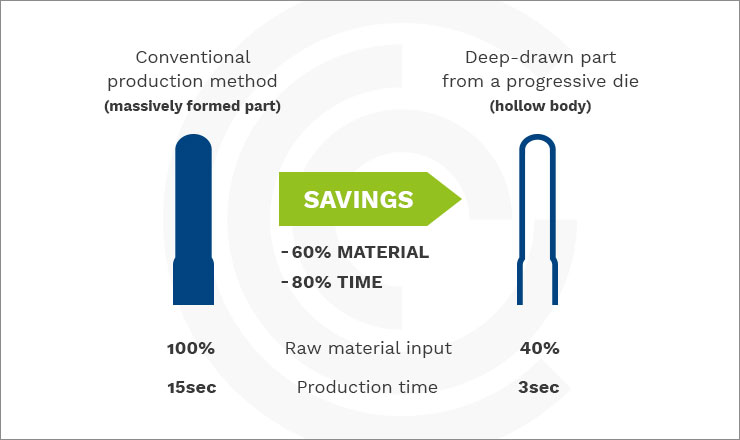

We are one of the few suppliers with extensive expertise in the development and design of deep-drawing tools. Compared to conventional manufacturing processes, enormous optimization potentials can often be exploited. For a major automobile manufacturer, we were now able to replace a massively formed component with a hollow body part produced by deep-drawing. The savings achieved speak for themselves: the machining time was reduced from 15 to 3 seconds, and the use of materials was reduced by 40 percent. However, this is by no means at the expense of quality. The deep-drawn parts have equivalent to better component properties.

Thanks to our modern production processes with state-of-the-art machinery and many years of experience, we are able to replace your conventional processes with appropriate deep-drawing processes. For this we use appropriate simulation procedures and our practical wealth of experience. Only after this theoretical approach do we go into the precise realisation of your individual deep-drawing tool. Would you like to replace your conventional production process with a more efficient one? Then please contact us now.