Full service

Everything from one source

As a system partner, we see ourselves as a partner to our clients, to whom we offer complete solutions from a single source – from personal advice, to planning and construction, to service in the areas of tool and pattern making, series production and try-out.

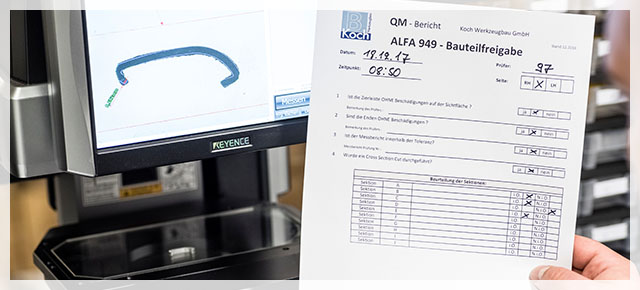

As your personal point of contact, we support you throughout the project and manage the processes. We can therefore react flexibly to your requirements at any time. Fast order processing ensures short delivery times. Quality is in our hands: We monitor all process steps, and manufacture to certified quality.

That means: We create the best conditions for the seamless integration of our products into your production processes.