Tool making

Solution partner for efficient production

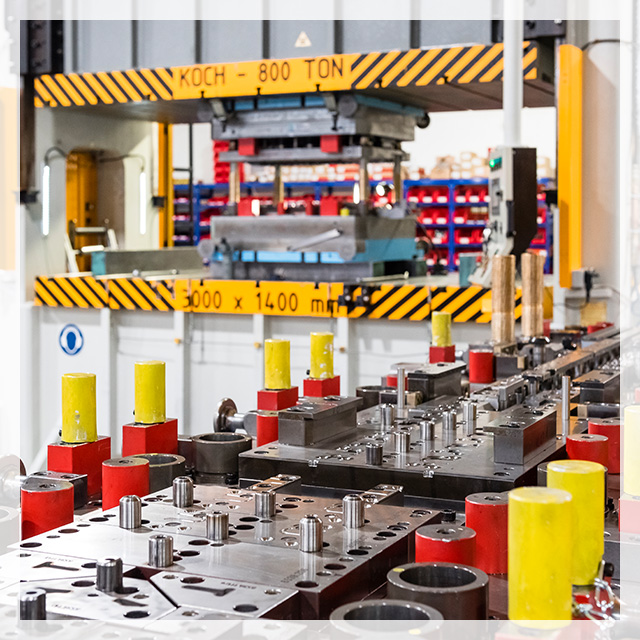

The roots of our company lie in tool making. We combine years of experience with the latest 3D technology. With high efficiency and absolute punctuality, we make tools for various industries. Our full service, from construction to final assembly, ensures complete quality assurance pursuant to DIN EN ISO 9001:2015, and flexible reactions to your requirements.

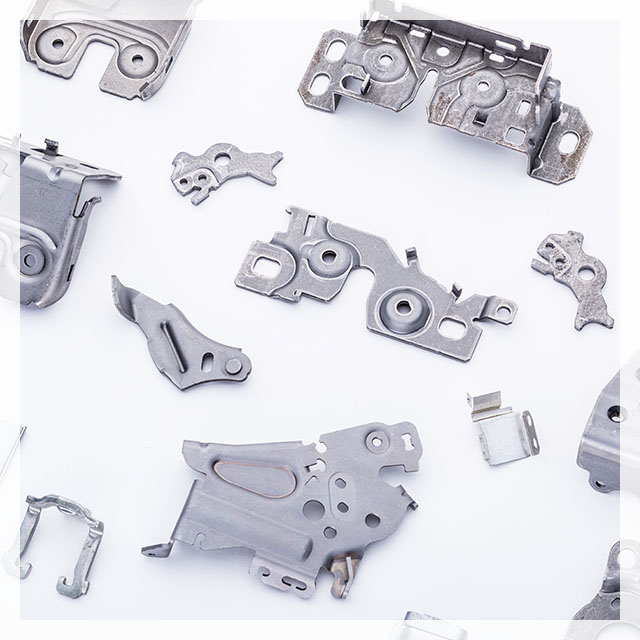

Punching, bending and drawing tools

We make punching, bending and drawing tools – also on commission – measuring up to a maximum of 3000 mm, in sheet iron, stainless steel, non-ferrous metal, and aluminium. We make punched parts with a plate thickness of up to 5 mm.

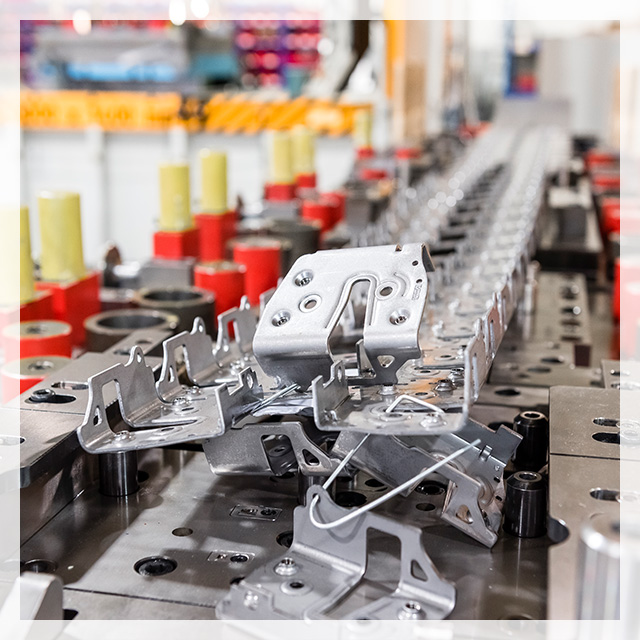

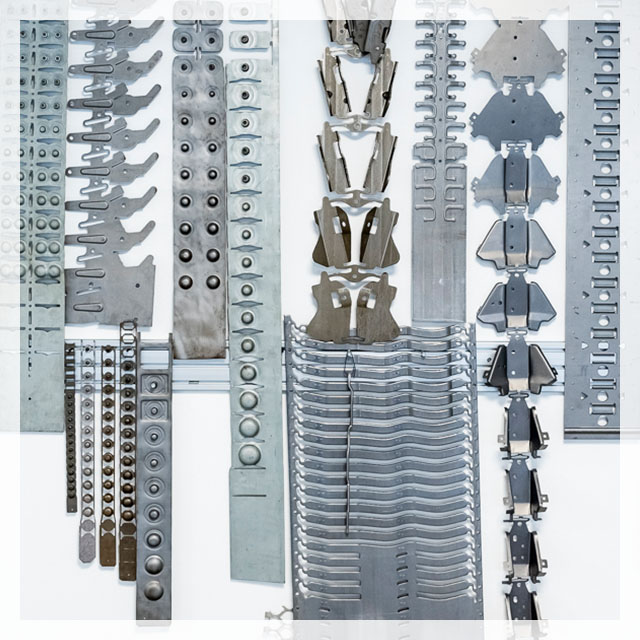

Progressive tools

We have special expertise in the field of progressive tools. We are recognized in Germany and abroad especially for our expertise in thermoforming progressive tools. Our production spectrum ranges from the millimetres-long precision sleeve, to the deep-drawn component which is several centimetres long and up to 5 mm thick, for the structural and bodywork sector in the automotive supply industry. We also manufacture progressive tools using thread forms, silver contact rivets and assembly technology.

Small batches

Because we offer all of our services from a single source, we can optimally coordinate and control our processes. This is particularly the case for tools produced in small batches. We develop and make these quickly and cheaply. The measurements and the initial sample test report (EMPB) are also included in our portfolio.