Service and maintenance for tools

The economical alternative to new investments

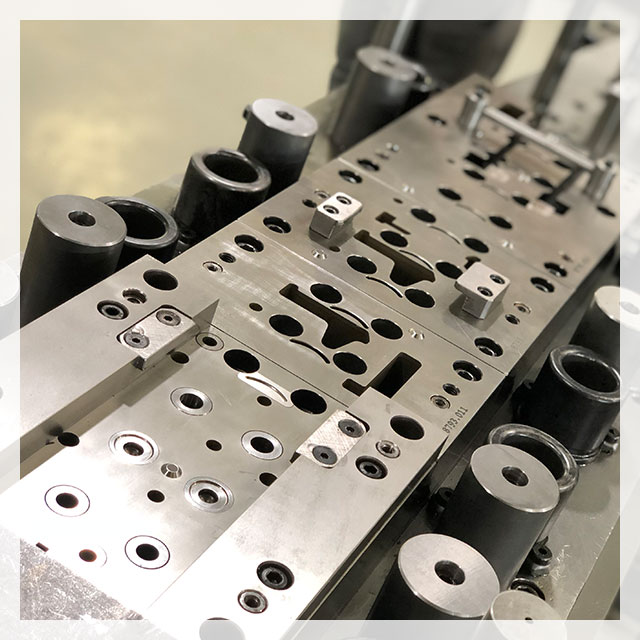

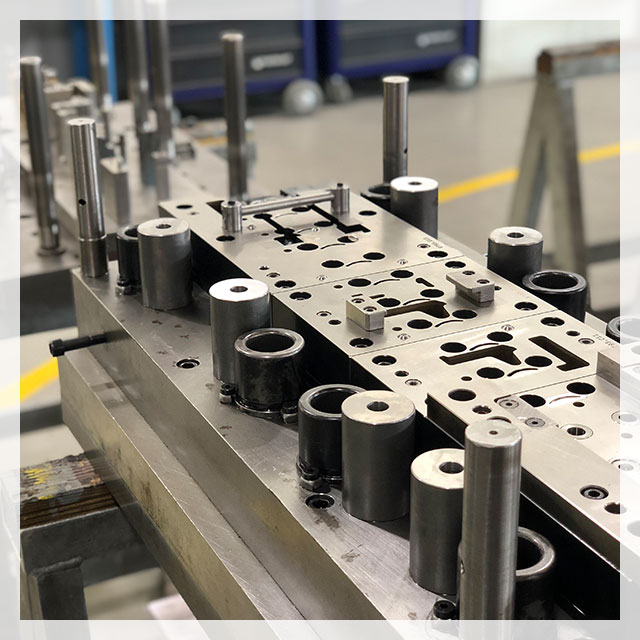

Wether punching tools, bending tools, deep-drawing tools or complex progressive dies – the quality of your tools and thus also the quality of your products suffers due to the continuous wear in practical use. However, in order to provide you with consistent quality for your production, as an experienced tool manufacturer we offer you comprehensive services in the area of service & maintenance for your tools. You benefit from modern maintenance procedures and many years of experience.

Service & maintenace for tools – Economically useful

hen you order a tool, you usually invest large sums of money. Therefore, our concept of service & maintenance for tools is an economically extremely sensible alternative to purchasing new tools. By regularly inspecting your tools, you can prevent major damage at an early stage and thus counteract unplanned downtimes. With our expertise, we can often offer a good alternative to costly new purchases, even in the event of major damage.

Service & maintenance for tools – Our competences

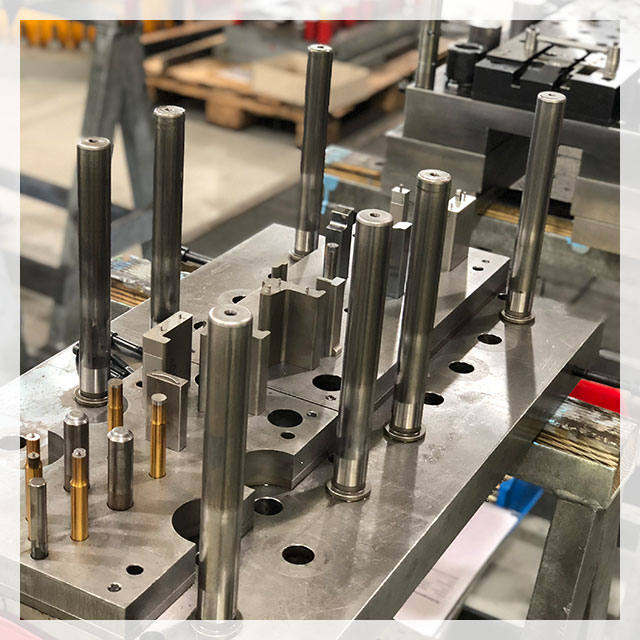

We are a renowned manufacturer of various tools, which we plan individually in coordination with our customers as well as realise precisely. This includes punching tools, bending tools, pressing tools, deep-drawing tools and special tools as well as complex special machines. Due to our practical knowledge regarding the production of appropriate solutions, we are able to offer you our services in the field of service & maintenance for tools in this entire spectrum. Here we do not limit ourselves to our own tools, but also repair tools from third party suppliers for you.

Service & maintenance for tools – We stand for quality

We stand for our established KochS quality in the production of a wide variety of new tool types. We use not only modern CNC machines, but also powerful measuring projectors. This procedure enabled us to obtain certification in accordance with the international quality standard ISO 9001:2015. Of course, we also offer you this quality promise in the area of service & maintenance for tools. If you have any questions, please do not hesitate to contact our experts.