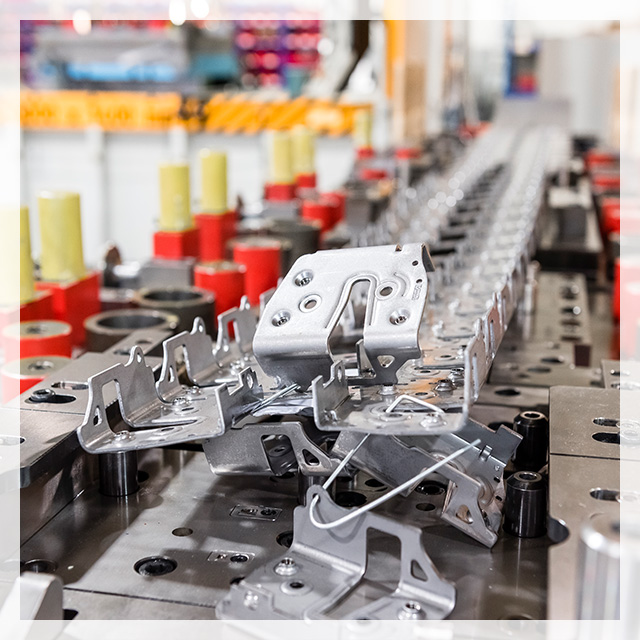

Modern CAD solution for tool design

Based on our many years of experience, we know that modern technologies are the key to trend-setting tools. Accordingly, in our daily work we rely on the powerful CAD solution VISI from the renowned Mecadat AG. This enables us to achieve maximum economic efficiency and reliability for our customers in the planning and design of tools.

CAD solution for tool design – application areas

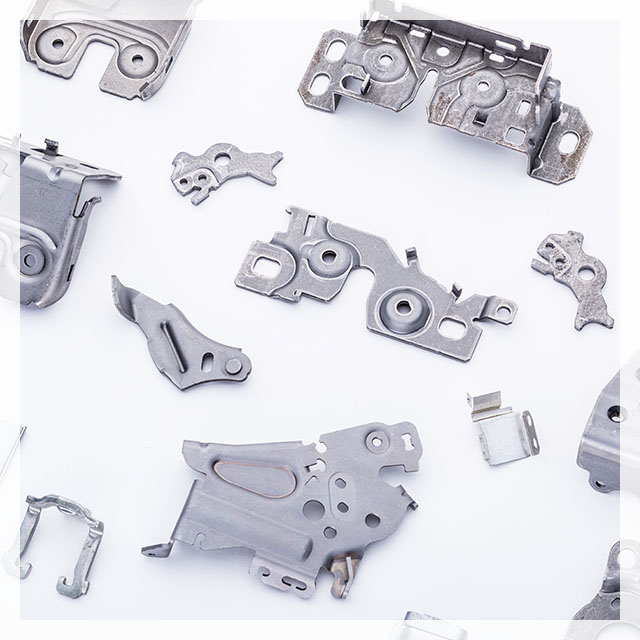

As experts in tool design, we offer our customers a wide range of services. In order to meet the respective requirements of the different tool groups, a flexible solution is required. VISI supports us in the design, calculation and production of the following tools:

- Bending-

- Cutting-, Punching tools

- Deep-drawn tools

- Thread pulling tools

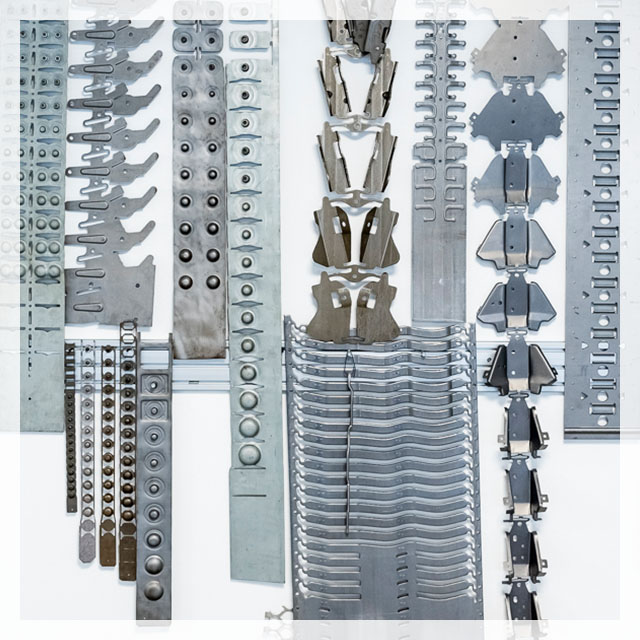

- Progressive Tools

- Bending tools

- Press tools

- Special machines

CAD solution for tool design – import of external data

We know from experience that the success of a tool depends on how closely our engineers work with those of our customers. That is why it is important to us that we use a CAD solution for tool design that allows seamless import of external data. Thanks to a large number of interfaces, VISI allows us to load data and projects from the following third-party programs: Parasolid, STEP, IGES, VDA-FS, DXF, DWG, Parasolid, Solid Works, Solid Edge, PEPS and Inventor. In addition, the integration of Catia V4, Catia V5, Catia V6, ProE/Creo, Siemens NX, SAT and JT-Open files is also optionally possible.

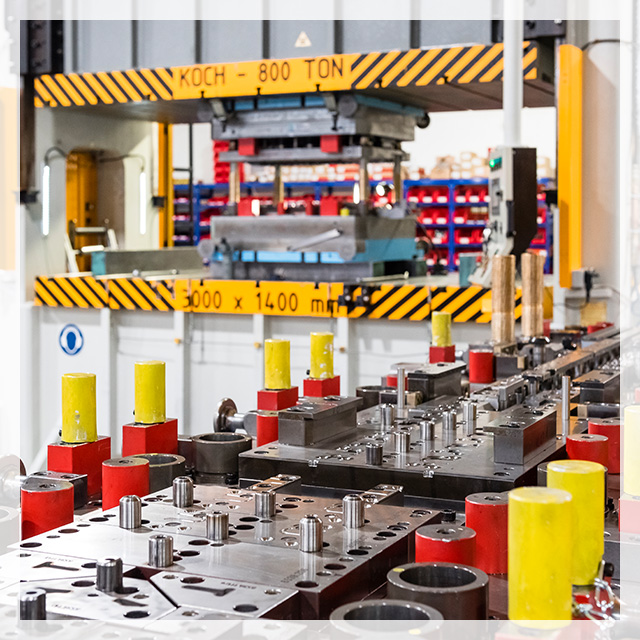

CAD solution for tool design – drawings and parts lists at a glance

For us the development of prototypes and the implementation of tryouts are routine. It is therefore important to us that we work with a CAD solution that offers added value. VISI supports us in particular by the automated creation of views and sections to detailed drawing sheets. Also, parts lists are created automatically. Components from catalogues are also displayed with all necessary information such as fit and thread specifications. Since we not only develop tools for our customers, but also carry out production in small to large series, this results in valuable advantages.